Candles

Do they belong to the realm of legends or were Goethe's last words really "Light, more light!"? We will probably never know. What we do know, however, is that poor lighting at that time and constantly smoking, sooty candles were a cause of great annoyance ... Read More

IDEAS & ADVICE

Candles. A Clean Solution.

Do they belong to the realm of legends or were Goethe's last words really "Light, more light!"? We will probably never know. What we do know, however, is that poor lighting at that time and constantly smoking, sooty candles were a cause of great annoyance to the famous German poet. "Nothing better could be invented than candles which burn without cleaning," complained Goethe in a letter to his close friend Charlotte von Stein in 1779.

It's not difficult to imagine him labouring over his books at night, every half an hour trimming back the wick of a permanently dripping candle – a process known in common German parlance as "schneuzen", which literally means "to blow your nose". But this was all a very long time ago. Not only have we enjoyed the luxury of electric lighting for many years now, but the quality of candles has also improved enormously since Goethe's days: the result of better-quality raw materials but also improved methods of wick production.

Coming out of the Shadows: A Brief History of Candles.

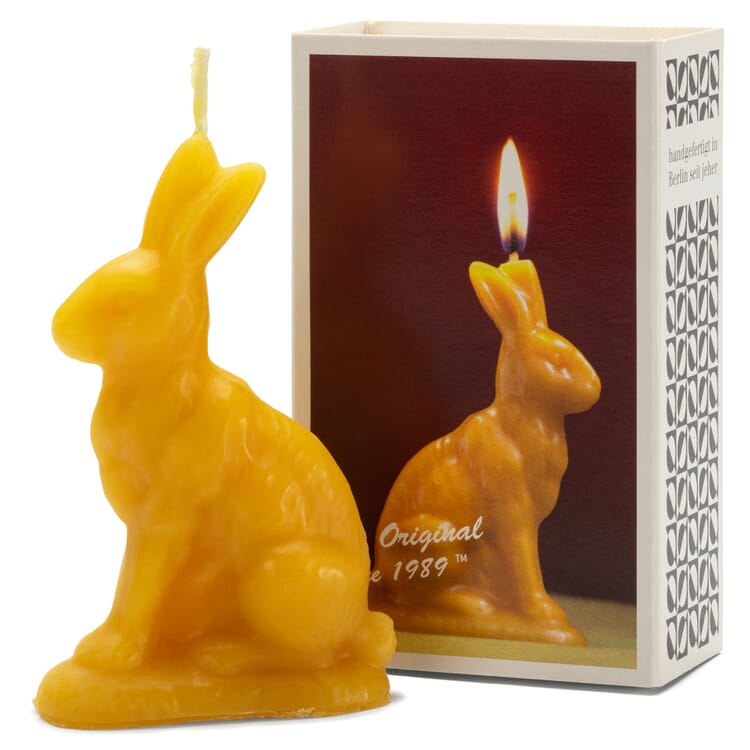

The first candles which provided light during the dark hours in the Middle East over 5,000 years ago were little more than straw, hemp or reeds soaked in fats or resin. The ancient Romans, however, used papyrus dipped in melted tallow, a rudimentary form of the wicked candle like those used by many other early civilisations. It doesn't take much imagination to picture how much smoke these early sources of light produced, and burning tallow cannot even euphemistically be classified as fragrant. By contrast, the first beeswax candles, which appeared from around the second century CE, emitted an agreeable smell and produced virtually no smoke. This was a major improvement indeed.

However, beeswax was scarce and expensive, which meant that until modern times only people of a certain social rank and with appropriate financial means enjoyed the luxury of these clean-burning sources of light. For centuries, average citizens had to make do with soot-producing, foul-smelling tallow candles. The 19th century finally heralded a revolution in the candle market. First of all, chemist Eugène Chevreul discovered a way of extracting stearic acid from animal fats, which culminated in the development of stearin wax, which was used in the production of candles for the first time from 1818. This was soon followed in the 1830s by paraffin, a by-product of the petroleum industry, which was far cheaper to produce than all other candle materials but burnt as cleanly and evenly as stearin and beeswax. Its only drawback was its low melting point, but this was usually overcome by adding stearin, which is significantly harder.

With the simultaneous improvement of wicks, which were now made of cotton and automatically curled sideways out of the flame as the candle burned – which in turn meant that the upper part glowed continuously and no longer had to be cleaned – Goethe's dream had come true. If only he had lived a few years longer.

Burning Pure and Clear. How to Identify Good-Quality Candles.

Discerning candle users have high standards. If possible, they want candles that

- do not drip or run

- produce no soot or smoke

- burn with a bright, even flame

- smell pleasant or, at least, not unpleasant

- burn for a long time and, if possible, burn down completely

- and are easy to relight

Most of these factors are determined by the method of production and choice of materials. In general, good-quality stearin, paraffin and beeswax produce high-quality candles. Beeswax is noted for its characteristic fragrance and is the only completely natural and unprocessed basic material. Deciding in favour of or against a particular type of wax is largely a matter of personal preference based upon origin, the type of wax, however, has no significant impact on the quality of the candles' burning properties.

Pure raw materials alone, however, do not automatically make good candles. It is also important that the wick is appropriate to the material, the material quantity and the diameter of the candle. Beeswax candles, for example, require a thicker wick than candles made of stearin or paraffin because of their consistency. The method of production, however – whether the candle is moulded, poured, pressed or kneaded – only affects the candle quality if the material is not sufficiently condensed, sometimes the case in pressed candles made of inferior-quality materials. At Manufactum, we value the artisanal manufacture by candle makers and wax modellers whose skills and expertise are directly reflected in the product.

Pillar Candle Beeswax

Scented Candle

Advent Candle Beeswax Small

What to Do If Candles Do Produce Soot.

To understand why candles produce soot, we first have to understand exactly how they function. After the wick is lit, the heat of the flame initially melts the wax near the wick. This occurs at temperatures of between 50 and 70°C, depending on the material. The liquid wax then rises up through the wick as a result of capillary action until it reaches the flame. It then vaporises and burns when exposed to oxygen, which in turn causes more wax to melt and keeps the cycle going. So theoretically, the wax diminishes, but the wick does not grow any shorter while it burns and does not itself come into contact with oxygen.

If this occurs, in other words, if the visible part of the wick becomes longer and longer, it also draws up more liquid wax, and the flame becomes bigger. Because a larger flame needs more fuel, or wax, but this cannot be supplied fast enough, the flame grows smaller again. If this continues to occur, the candle splutters and in turn produces soot. This is only a very condensed version of the processes that take place. The physical and chemical principles behind a burning candle are actually so complex that scientist Michael Faraday held a six-part Christmas lecture on the subject in the year 1860.

Thanks to improvements in wick construction, the problem of soot production can now be effectively avoided. To achieve this, cotton threads are asymmetrically woven and reinforced on one side with string threads. This causes the tip of the wick to bend sideways when burning, which exposes it to oxygen and makes it combust. If there is a weaving defect, however, as is sometimes the case with inferior-quality wicks, the wick might stand too upright, bend too much, twist like a corkscrew or produce mushroom forms. So a soot-producing candle may be a sign of poor production methods.

Wicks that become too long and visibly emit soot should be carefully trimmed when extinguished with a pair of (wick) scissors. The ideal wick length is between 10 and 15 millimetres. Make sure no wick particles or ash drop into the wax pool because impurities in the wax can cause the candle to burn unevenly and drip.

Production defects, however, are far less likely to cause flickering and soot than exposure to drafts. So never place candles in areas that are exposed to continual movements of air. Lack of oxygen supply, however, can also have a negative effect on burning behaviour. Unsuitable candle holders may restrict air supply, as can a high ring of wax around the outside edge, which occurs when the wax has not melted to the edges of the candle before it is extinguished. If this is unavoidable, remove the wax edge when still warm and soft with a sharp knife to ensure the candle does not burn on a low flame. Even the best candles will be unable to perform to their full potential if these factors are ignored.

Spot On. Effectively Removing Candle Wax.

There are basically two ways to remove wax stains: with heat or cold, depending on the material that is affected. In some cases, a combination of both methods is needed. If possible, crumble off as much wax as possible before further treatment. This is usually easy on textiles as soon as the wax has cooled. Never try to treat the stain before the wax has completely dried because this could make the problem worse.

- If it is difficult to remove wax residue from textiles or leather, to apply cold is the best method. Depending on size, temporarily place the object in your freezer, or affix an ice pack (protect leather objects against condensation by wrapping the ice pack in a cloth) or use a cold spray.

- The reduced temperature makes it easier to remove the brittle wax. Thinner wax residues on other textiles which cannot be removed in this way can be melted with an iron and drawn out of the fabric with a layer of absorbent material, such as blotting paper or a paper towel. Set the iron to a medium heat and avoid using the steam function. This method is not suitable for sensitive textiles or coloured wax: after crumbling off as much wax as possible from such items, consult a dry cleaner.

- If you want to de-wax metal candelabras or candle glasses, soak them in warm but not boiling water. The softened wax should then be easy to remove. Larger objects that do not fit in a bath tub can be de-waxed using a hairdryer. Simply wipe off the softened wax with a paper towel.