Exclusive

Great Craftsmanship. Our leather collection

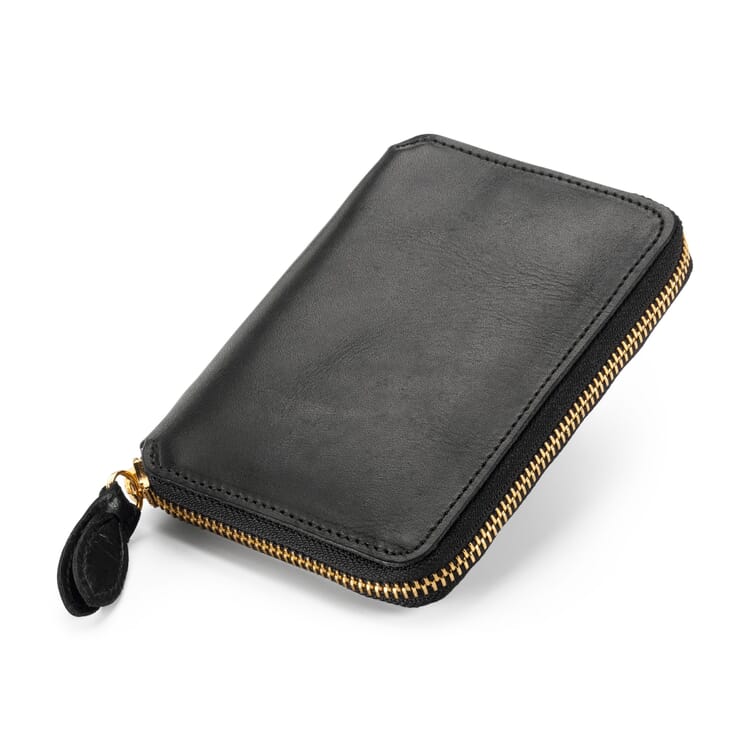

Our leather collection is made with sense and attention to detail, from the leather to the last seam. The small leather goods are unlined; the back of the leather thus remains - with its natural irregularities - "honestly" recognizable. Their seams are finished with an open edge. The hides come from German cattle, mainly from southern Germany. They are vegetable tanned in Germany in barrel tanning, i.e. in slowly rotating oak barrels in a tanning broth, each of whose vegetable ingredients leaves its specific effect on the tanned leather: from mimosa, the bark tanning agent of the black acacia, and from quebracho wood it receives its excellent grip, from the tanning agents of the sweet chestnut its beautiful reddish hue. Many items are also available in black.

Selected Products

Few wallets fold so elegantly: The unlined coin compartment is opened by turning the flaps 90 degrees and closed in the same way. On the bottom of our folding wallet is an additional compartment for bills, which is closed with a hidden brass snap fastener.

A classic men's wallet with five card slots protected by a flap - with three additional card slots. With two bill compartments and a long compartment behind the credit card compartments, which provides space for the car bill, for example. Coin pocket lined with leather.

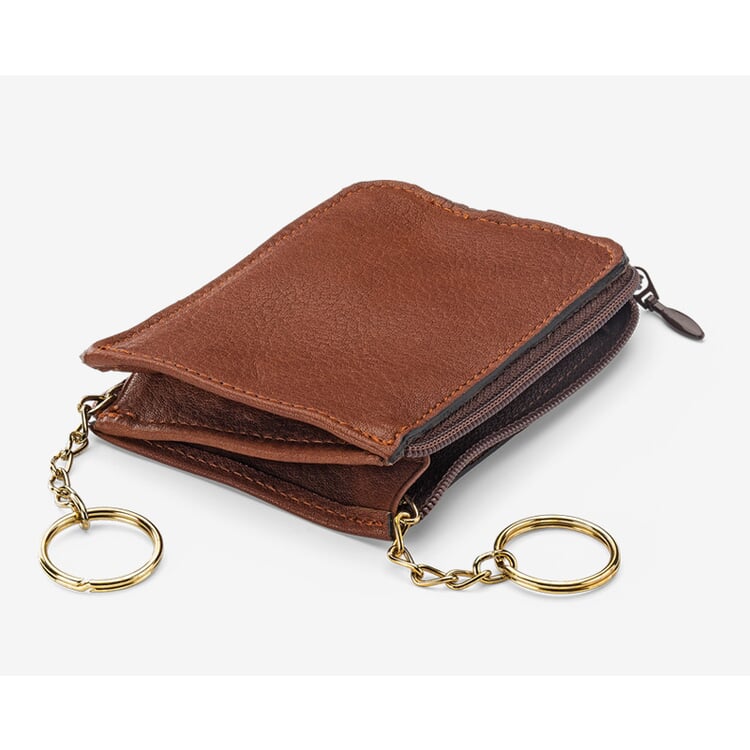

The key case consists of two zippered pockets, each of which can hold keys - or even a few coins and small folded bills. Two leather wedges incorporated into the sides ensure that the case can be closed even with voluminous contents. The two key rings are attached to 7 cm long chains, which in turn are riveted together for safety.

The products at a glance

The finishing, i.e. what subsequently happens to the leather that has become tanned in the barrel, is the big difference to everything that is common today: In order to take the brittleness out of the 1.6-1.8 mm thick leather and to make it supple and durable, it must be "soaked" and greased after tanning. This has been done since the middle of the 19th century, not to mention today's processes, with animal tallow, the so-called tanner's fat or "dégras". We go back a stage further and resort to the means to which, according to connoisseurs, the legendary old Russia leather owes its reputation: fish oil and wood tar. In the rotating fulling barrel, the ancient fatliquors cod oil and birch bark tar give the leather a lasting suppleness that is perfected over time, while the birch bark tar impregnates the leather in a natural way.

Tanning is the process by which animal hide acquires its resistance to water and decay. Protein fiber is converted into leather fiber - a process, by the way, that cannot be replicated synthetically. In addition to the nature of the raw material, the type of tanning determines the quality and properties of the leather end product: strength, stretchability, water tolerance, and also the properties of the surface such as hardness or suppleness are largely determined by the tanning process.