- Outdoor lighting design

- Balcony fruit. Rich harvest in the smallest space

- Bella crema. Tips for the preparation of espresso

- Create and green Benjes hedges

- Bee friendly perennials

- Tying variants for scarves

- Flowering ornamental shrubs. 12 tips on selection, location and care

- How to bake bread

- Bullet Journal. Ideas for a creatively designed notebook

- The right juicer. A question of type

- The classic shave with razor and straight razor

- The optimal wet shave

- The advantages of a badger hair brush

- The choice of coffee maker

- Choosing the right pillow

- How to make ice cream and sorbets

- Against thirst. Drinking bottles

- Barbecue with the Big Green Egg

- Recognize good kitchen knives

- Good pocket knives

- How to recognize a good tool

- Shirt collar. Small collar science

- Coffee. From the bush to roasting

- Making coffee. Completely without pressure

- Which pan for which purpose?

- How to Pack a Suitcase

- Knife Sharpening & Sharpening

- Naturally antistatic. Carpets from natural fibers

- Sleep well, of course. With the right bedding

- How to make Pasta

- Wet Shaving or Dry Shaving?

- Plant propagation. About cuttings or seeds

- Robust and functional. Travel bags

- Scissors science. Garden shears for every purpose

- How to Care for Shoes

- How to make soap

- Tips for buying shoes. How should shoes fit?

- Which planter for which plant?

- How to recognize a good espresso

- How to recognize a good garden table

Helpful tips

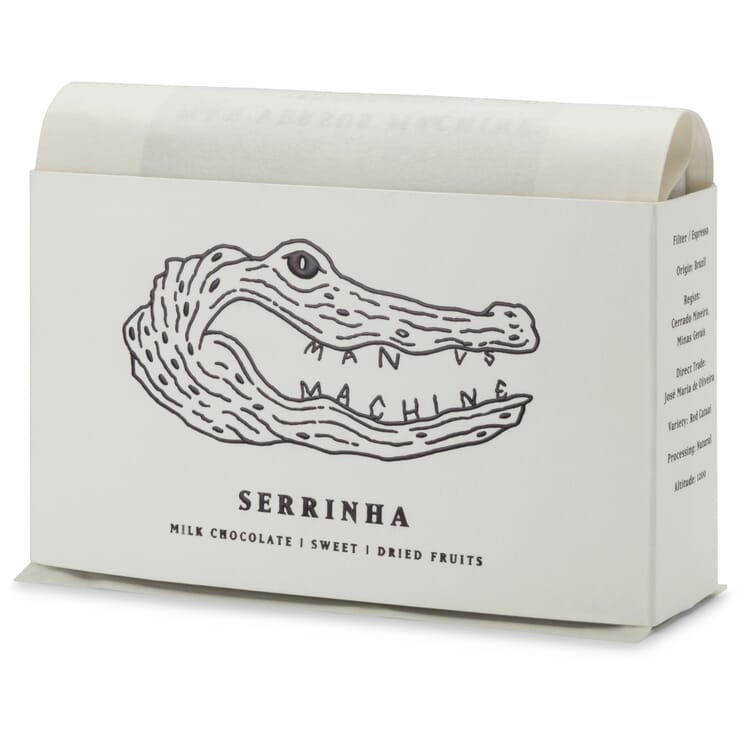

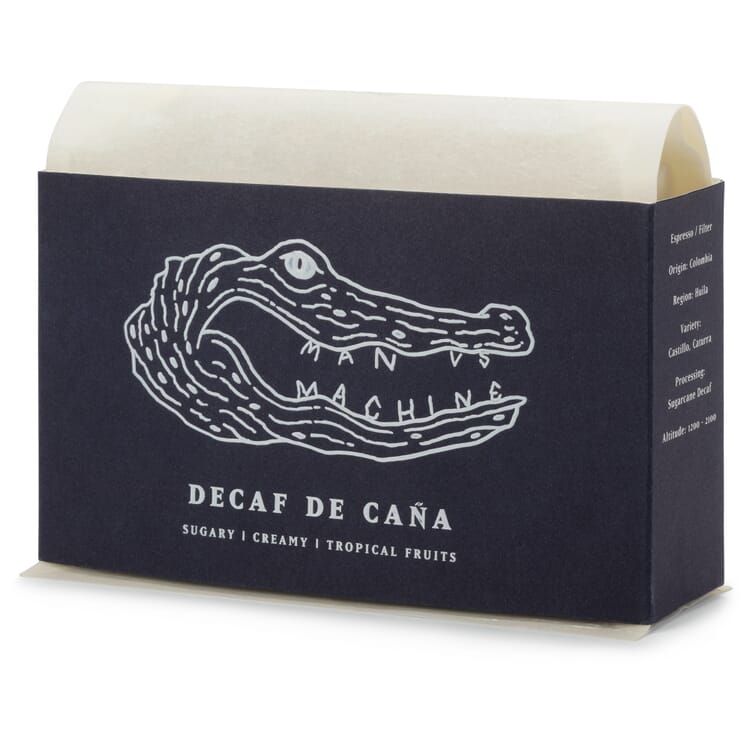

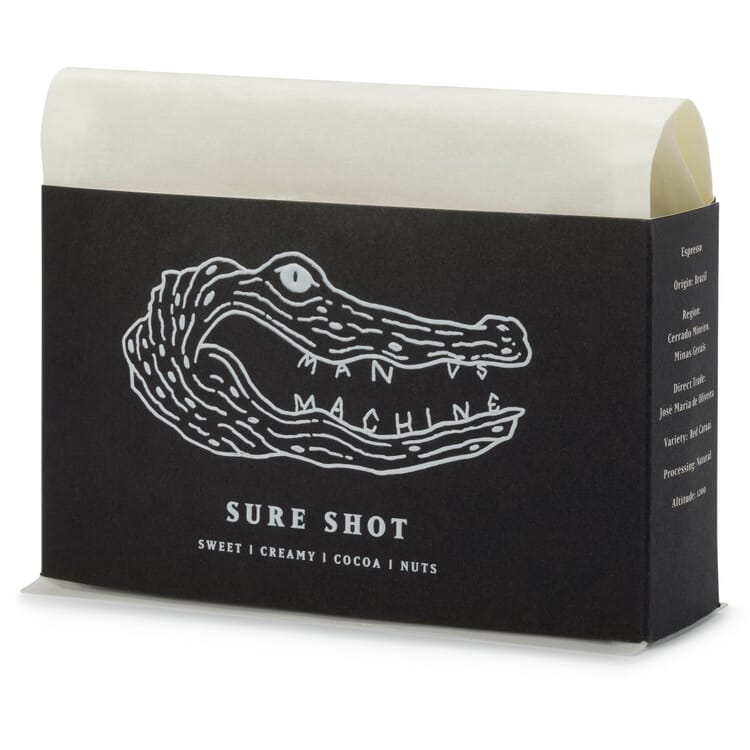

Fine coffee. From the bush to the roasting

If you look at the quantities of coffee consumed in Germany every year, you could almost come to the conclusion that public life would collapse without the black brew. Some people wouldn't even get out of bed, let alone leave the house, and work output in the nation's offices would drop dramatically. Coffee is the tool of choice to wake up, to get out of a hole of inspiration, and casual communication at the coffee machine not only promotes the working atmosphere, but also creativity. Hardly anyone thinks about where the coffee actually comes from and the routes it takes before it finally ends up steaming hot in the cup.

The coffee bean. Made naked

For many people, coffee is simply a darkbraunes, seductively fragrant powder that comes out of a bag. So far, so good, and so far from reality. For even the roasted coffee bean, the precursor of the powder and still familiar to a large part of the population, is already a very widely processed product, at the beginning of which there is a shrub from the roasting family. A shrub that bears small, oval, red fruits, inside of which are usually two seeds that look at each other in their fleshy envelope with the flattened sides: the coffee beans. If you peel off the fruity-sweet pulp, they reveal themselves in their naked rawness: slimy, surrounded by a parchment as well as a silver skin and, depending on the variety, from yellowish to blue-green in color. Although there are around 40 different types of coffee, only a handful are grown, and only two are important for the world market: Arabica and Robusta.

The coffee plant. A real sensitive

For coffee to thrive, it needs some climatic conditions. Temperatures should be balanced during the day and at night, all year round, without extreme heat or cold. The plant also needs sufficient rainfall and, ideally, plenty of shade. Too much wind, on the other hand, can be detrimental. It is no wonder that the areas around the equator provide the best conditions for coffee cultivation. This area is therefore also known as the coffee belt. The optimal growing areas differ depending on the type of coffee: While Arabica grows primarily at altitudes between 600 and 2,100 meters, Robusta thrives at lower altitudes between 300 and 900 meters. The higher the altitude, the lower the average temperature and the slower the coffee cherry grows. As a result, Arabica is the coffee that demands more patience from the producer, but the longer ripening period also gives it the opportunity to develop more varied and stronger aromas. Soil conditions also play a non-negligible role if one wants to produce a particularly aromatic coffee. It should be deep, loose, well aerated, and rich in nutrients and humus. Ideally, the pH value should be between 5 and 6, which means that it tends to be a little acidic, but otherwise neutral. Volcanic soils, for example, offer optimal conditions for coffee cultivation. Coffee plants develop best on slopes or in forest gardens between shade trees; on dedicated coffee plantations, darkening nets are usually used as an alternative.

Arabica and Robusta. Two coffees, two profiles

Coffee made from Arabica beans is generally regarded as the more noble variety compared to Robusta. Although this definition is somewhat short-sighted, since a good Robusta is certainly preferable to a poor Arabica, the statement is sufficient for an initial classification. The following aspects also distinguish Arabica from Robusta:

- With a share of around 60-70% of world market production, Arabica, which originally comes from Ethiopia, clearly outperforms its competitor from West and Central Africa, which only accounts for just over 30%;

- The fruits of the Arabica variety need nine to eleven months to ripen. Robusta fruits, on the other hand, are already ripe six to eight months after fertilization. With up to 1.5% caffeine content, Arabica is significantly lower than Robusta, whose caffeine content averages 2.7%. The content of the potentially stomach-irritating chlorogenic acid is also about twice as high in Robusta as in Arabica.

- Visually, the beans can be distinguished by their shape: Arabica beans are characterized by a curved indentation, while Robusta has a straight indentation.

- The Arabica plant is the only self-pollinator genus-wide. The Robusta plant is therefore dependent on cross-pollination. Robusta lives up to its name: Significantly less sensitive to disease, heat and humidity, it noticeably outperforms Arabica in terms of resistance. The latter is prone to coffee rust if grown at too low an altitude and at higher temperatures.

- In terms of taste, a coffee made from Arabica beans is more nuanced and refined than a Robusta, it has fine fruit acids and comes across as light and clear. The Robusta tastes more earthy and less differentiated, is slightly more bitter than the Arabica, but impresses with a fuller body and strong aroma. While there are countless varieties under the genus Coffea arabica, some of which differ significantly from one another, Robusta is already a variety belonging to the genus Coffea canephora. As a rule, therefore, there will be fewer surprises in terms of taste here.

Wet processing and dry processing. The further processing of the beans

After harvesting, the coffee cherries require rapid further processing in order to anticipate the fermentation process, which begins just a few hours after harvesting. A basic distinction is made between wet and dry processing, although mixed forms exist in practice. Wet processing is generally considered to be the higher-quality variant, since a purely sun-dried coffee can quickly taste fermented, while a washed coffee comes across as clearer and more finely nuanced. However, using high-quality aids such as advanced drying tables and nets, as well as well-trained personnel, taste degradation can be prevented. This is particularly interesting in view of the fact that wet processing requires large quantities of water.

How wet processing works:

- First, the coffee cherries are pre-cleaned with water.

- Next, the "de-pulper" is used, which squeezes the fruit skin and flesh from the beans, but leaves the parchment skin and mucilage on the seeds. In a fermentation tank, fermentation now takes place, with the aim of liquefying the mucilage and then washing it off. For this purpose, the beans remain in the water bath for 12 to 36 hours. The beans are then dried, either in the sun, where they are regularly turned and covered if the heat is too strong, or mechanically with hot air. Sun drying takes about 8 to 15 days

- Finally, a peeling machine removes the dried parchment and silver skins.

Dry processing requires fewer steps:

- Here, the coffee fruits are laid out to dry in their entirety. A total of three to five weeks are estimated until the fruits have shrunk to a water content of 12%. The correct degree of dryness can be checked by shaking: If the bean rattles in the dry hull, the coffee is ready for further processing

- This involves mechanically peeling off the skin and dried pulp. The parchment skin, on the other hand, is not removed until shortly before transport

- An advantage of dry processing: **The mucilaginous pectin layer is absorbed into the coffee bean, giving it a sweet aroma.

Getting a taste for it. The coffee roasting

The final step in processing coffee beans ready for consumption is roasting. This step is also considered refinement, because it is only through dry and fat-free heating that the diverse aromas in the coffee are released

A distinction must be made between high-quality drum roasting and industrial hot-air roasting

- Industrial roasting is a time-saving variant that takes place at temperatures of up to 550 °C. The problem is that the coffee beans are not roasted evenly but are potentially not yet "through" on the inside. The problem: The coffee beans are not roasted evenly with this method, but are potentially not yet "through" on the inside, while the first signs of charring are already showing on the outside. As a result, a large proportion of the chlorogenic acids remain in the beans, which can cause irritation in sensitive stomachs. In addition, the roasted bean is often cooled with water instead of air during this process, which offsets the weight loss during roasting, which can be as much as 20%.

- The traditional process of drum roasting** is not only gentler on the bean, but the coffee produced in this way is also gentler on the customer's stomach. The maximum temperature here is 200-250 °C, which means that the roasting process takes considerably longer, but pollutants can be better removed and more varied aromas can be built up.

In general, the following applies in connection with roasting:

- Up to 1,000 different aromas can be formed during the roasting process. No one can easily fool coffee in this respect. Even wine offers only a fraction of the flavor nuances. Take your time to taste a high-quality coffee

- light roasts taste more sour and fruity and less bitter, darker roasts, on the other hand, are strong and spicy with a slightly sweet aroma

- just a few seconds' difference in roasting can produce distinctly different tasting coffees from the same raw material. The skill of the roast master and the effects of his actions on the taste potential of the end product should therefore not be underestimated.

With this in mind, enjoy. With our coffee and espresso varieties, you can be sure that raw material, further processing and roasting culminate in an incomparable taste experience. For this, you don't even have to read the coffee grounds. Rather, it is a logical consequence.