Manufacturer

Cuboro® marble run. Winding paths to success

For decades, glass balls have been rolling along intricate paths through the Cuboro® ball tracks from the Swiss canton of Bern. Even if the first own constructive attempts do not work smoothly yet, already the tinkering and trying out give great pleasure: This is not only the way to describe playing with the marble run, but also the entrepreneurial path that originator and designer Matthias Etter has taken with Cuboro®.

The story begins in the 1970s, when the trained special educator Matthias Etter is working at a special school in Bern. In his work with children and young people with disabilities, Etter was missing a learning aid that appealed to the students on several levels: one that allowed them to touch and look at things on the level of sensory perception, one that encouraged them on a creative level to constantly experiment and make new discoveries, and one that supported and encouraged them in their fine-motor as well as cognitive development. It is not only in special education work that it is obvious that such a complex learning aid must also be quick and easy to grasp - and fun. After all, disappointment stands in the way of any learning effect, but the joy of playing keeps people engaged all by itself. Based on this insight, Etter designs a marble run that can be constructed and built like a variably combinable, entertaining puzzle game.

Complex system. Pleasurable sense of achievement

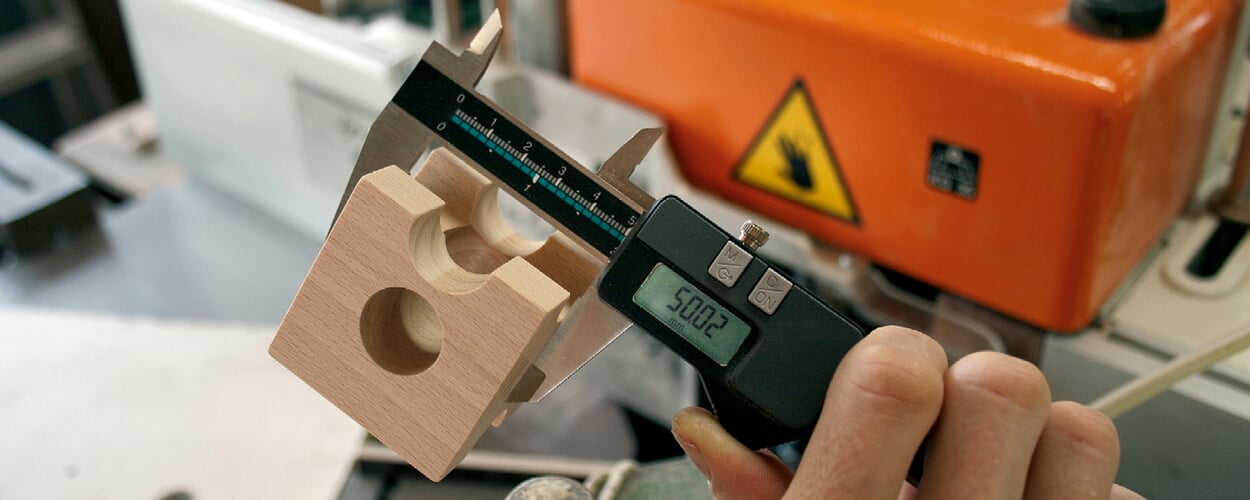

The basic shape of the Cuboro® track is cubes with an edge length of five centimeters and incorporated grooves and holes. Up to four functions can be connected to the cubes on the surface and inside. The system opens up countless combination possibilities; the only limits are set by the laws of physics. The path to a track along which the ball can roll swiftly varies according to the age and talent of the players. However, regardless of whether the goal is reached through thought, trial and error or imitation, the end result is a sense of achievement and the experience that a functioning system is created through the sensible combination of individual parts. In order to be able to implement this idea, Etter initially experimented with clay cubes, and the working group of the small school pottery was committed to assisting him in their manufacture. The first clay model from 1976 already showed the constructional features of the later Cuboro® cubes, but did not yet prove to be optimal: too imprecise in the path guidance, too fragile in handling. Building on this simple precursor, Etter develops a prototype made of fir wood, but even this relatively soft and light wood does not yet satisfy him. That's why he finally opts for the hard-wearing beech wood: in addition to its natural robustness, it brings with it a solid inherent weight, so that the cubes can be combined to form a ball track that is stable in itself. This enables Etter to have a small series of wooden cubes made, still rather crudely, which he offers at the Christmas market in Bern in 1985.

From the quiet room to the world market

The demand encourages him to take the next step. Etter refines the concept, but fails to find a company that considers his idea marketable. So, without further ado, he applies for a stand himself at a relevant trade fair in Bern. Thanks to his powers of persuasion and the obligingness of the trade fair management, he was able to get a stand, despite the usual registration deadlines and waiting times of several years: in a side aisle between the toilet doors. A secluded spot, but one where all trade fair buyers inevitably pass by - and with them the first orders.

From this point on, things go steadily upwards, and the popularity of the Cuboro® marble run grows internationally as well. Supported by family and friends, Etter was able to professionalize production more and more and finally founded Cuboro AG in 1997. Only eight years later, at the 2005 World Exhibition in the Japanese prefecture of Aichi, Cuboro® was even among the "Best of Switzerland Products". A success to which the family business is continuously committed: Looking to the future, Matthias Etter hands over the management of Cuboro AG to his son Sebastian in 2020.

Swiss made. Made from Swiss wood

Sebastian Etter continues to uphold the company's tradition and pays attention to responsible production. After all, such a complex system requires manufacturing whose precision far exceeds the usual standards of the woodworking industry. From the very beginning of its development, Cuboro® has found in Nyfeler Holzwaren AG a family-run, experienced joinery whose employees guarantee this dimensional accuracy with craftsmanship and many years of know-how.

Situated in the densely wooded hilly landscape of the Bernese Pre-Alps, Nyfeler processes for Cuboro® exclusively beech trunks with straight growth and without warping or knots. The beech trees come from the surrounding forests, and their wood is certified as Swiss wood. This not only has the advantage of environmentally friendly forest management and extremely short transport distances. In contrast to the valley location near the river, which has been typical for sawmills for centuries, the climatic conditions of the wind-swept hilly landscape favor a fast drying process. Up here, instead of the usual three to four years, the beech planks need only one year to dry thoroughly and eliminate the possibility of later stress cracks. An additional ecological bonus is that the careful drying process can be carried out without the use of insecticides. Thanks to the rapid process, pests do not even have enough time to settle in deeper and impair the quality of the wood before the Cuboro® cubes are removed and the track elements are incorporated into them.

Maximum performance in precision. Feats for generations

Up to 30 work steps are required to complete an element. In the process, the master carpenters achieve a feat of precision and feats such as horizontal curve drilling that even amaze experts. In this quality, the cubes retain their exact shape for many years - as does the playing pleasure, which lasts a lifetime.

Additional sets, which contain cubes with an even more complex construction and elements with special functions, further increase the playful challenge. Particularly impressive: all the elements and sets Cuboro® has ever produced are compatible with each other. So anyone who bought a building set years ago or inherited an older edition can add a younger building set to the existing set at any time.

Recommended Topics

The first Kösen doll factory was founded by Käthe Kruse in 1912. It left the GDR in 1949, but the special doll-making skills that had developed over four decades remained. The company specialized in the production of soft toys, and the creative demands also grew steadily as a result of the cooperation with the neighbouring Burg Giebichenstein - one of the most important training centres for product design in Germany since the beginning of the 20th century - which had grown even longer in the meantime.

View more