Manufacturer

Pasta with tradition. From Cavalieri

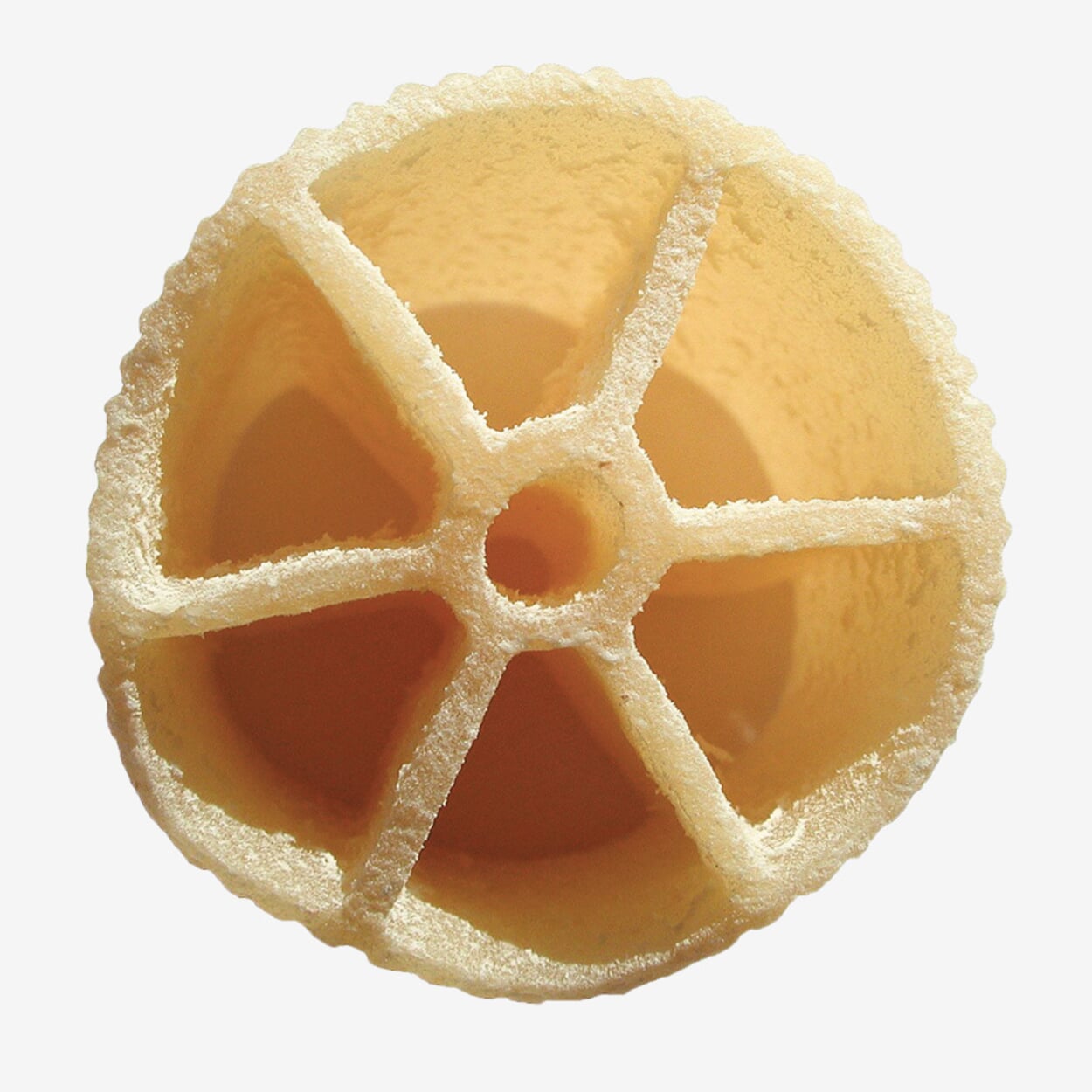

To produce good pasta requires selected ingredients and craftsmanship. The basis is non-standard durum wheat varieties, which combine their best properties in the flour mixture. When water is added to the flour, kneading at a maximum of 35 °C (and only then) causes the proteins of the grain to form the glutin, which is essential for the gelatinization of the pasta during cooking. The dough, which is prepared in different ways depending on the pasta format, is slowly pressed through bronze scribes, which results in a rough surface that allows the pasta to bond better with the sauce. Finally, the pasta is dried, which takes several days for artisan producers, at temperatures that never exceed 60 °C. To produce the best possible pasta in this way takes decades of experience.

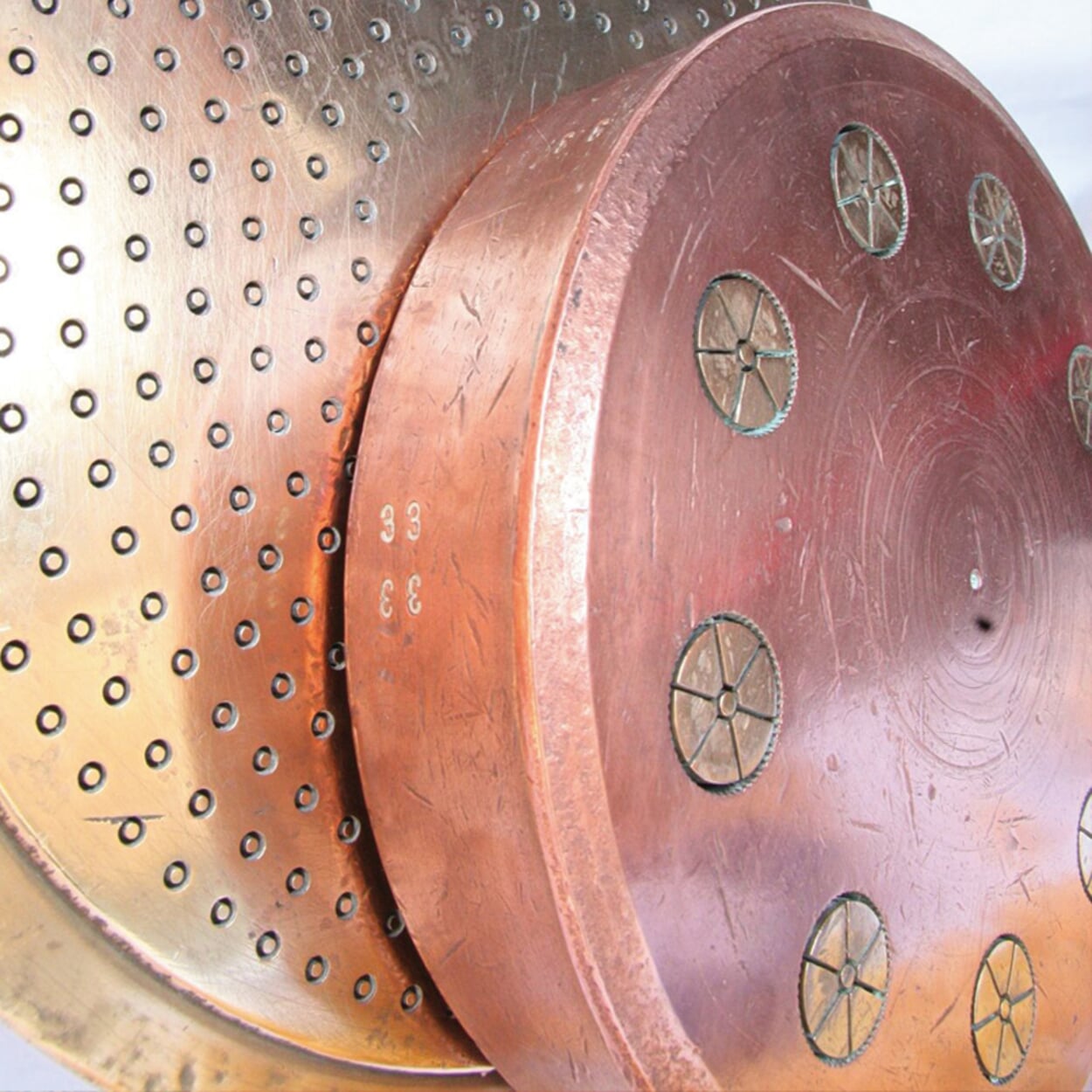

Bronze mold for making the ruote pazze

Rough surface of the finished pasta

Deail shot of the spaghettoni

Pasta Cavalieri. Since 1918

In the Benedetto Cavalieri company in Apulia, founded in 1918, only durum wheat from the region is used for pasta. It contains less protein and gluten than the often used Canadian durum wheat and is also less intensively colored, but it provides pasta that is characterized by its highly aromatic flavor and unique bite strength. For the production of Cavalieri pasta one follows the "metodo delicato", the gentle method. The dough is made in a different way for each pasta format and is specially adapted to it. However, the dough is always kneaded for a long time before being slowly pressed at low pressure through bronze molds. The pasta is also left to dry for up to 44 hours at a low temperature, before being left to rest and stabilize for 24 hours in climatic chambers.

Cavalieri pasta

Recommended Topics

Fresh, homemade pasta is as good as a short vacation in Italy. Whether garganelli or tagliatelle, every Italian region cultivates its own specialties. In fact, there are hardly any limits to the variety of shapes. Whichever format you choose, preparing homemade pasta is much less complicated than you might think.

View more